PROJECTS: Bridgeport Series II

Bridgeport Series II

This Bridgeport series II Interact 2 machine had worked fine

since I acquired it in 2003. It had a Heidenhain TNC 151 control that is easy

to program in either of 2 languages. The controller has features to machine

contours and pockets and is easily programmed without CAD/CAM tools. Recently

when I went to finish a job that I had started I found the control would no

longer initialize. After checking the power supply, some of the voltages looked

wrong. I don't have schematics for the controller so this seemed like a good time

to upgrade the control to EMC2.

The old Heidenhain contoller:

Existing cabinet:

The large transformer in the lower left is for the servo

drives. Three servo drives are located in the lower right of the white panel.

Just above the servo drives are common mode inductors for the servo motor power

for each drive. The other transformer in the lower right is for aux outlet

power on the back of the machine and is not needed. In order to mount the PC

mother board in the cabinet I relocated the servo transformer.

The schematic picture shown above shows one of the servo drives.

Note that these servos use an analog +/- 10V velocity command for input and use a

tachometer on the motor for velocity feedback. This should make the control

relatively easy to setup as I only need to close the outer position loop with EMC.

The new PC motherboard was the ECS Goal-3 referenced on the Linuxcnc

web site. For I/O I selected the Mesa 5i20 with one 7I33TA and one 7I37TA. In the future

I hope to use a drive for the spindle and add a spindle encoder.

For the initial setup I just used halrun with a test hal file. This way

I could test to see that the motors moved according to the command signal and check

the position encoder feedback. This was the first setback in the project as I found that

the Heidenhain encoders produced analog sine and cosine 125 cycle/revolution output signals.

So to handle the encoder output problem I took the encoder interface board from the old

Heidenhain controller and mounted it on the back of the cabinet door close to the PC. The

Heidenhain board then outputs 625 A quad B digital cycles per revolution giving a resolution

of 2500 counts per revolution. The ball screws have a 5mm pitch and are driven by a 2:1

timing belt reduction from the motors. So 2500 counts of the encoder represents 2.5 mm of

motion or .001mm per count.

Control Cabinet with PC:

Heidenhain Encoder Board:

After I had the new control running I needed to have a display

and keyboard. I decided to use the existing pendant. I have a 17" LCD display

which just fits in the width of the pendant. So I needed to do some cutting and

welding to get the display to fit. With the 17" display there was no room left for

some of the buttons that I wanted from the old controls, so I added a 3" X 3" square tube

to mount the buttons.

Modified Pendant:

Extra Buttons:

Finally I had an industrial water resistant keyboard that I wanted to

mount on the front of the pendant. I used the cnc machine to make some mounting

brackets that use 1/4" pins so the keyboard can easily be removed if necessary. I

needed to fill the hole in the top of the pendant with something so I painted a piece

of 1/4" acrylic black then cut the "EMC2 AXIS" with a .031" dia end mill and put a small

light behind it.

Finished Pendant:

Finished Machine:

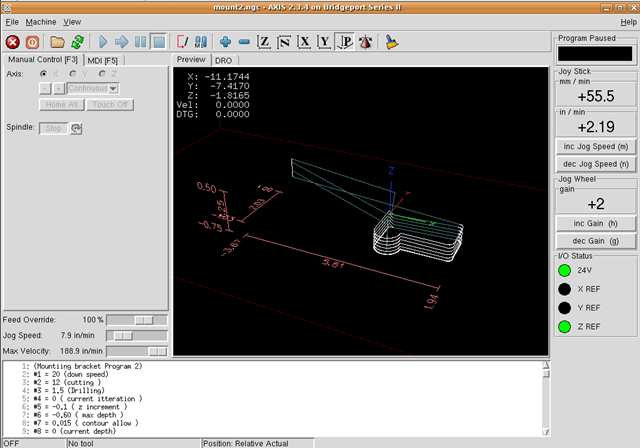

For others that may be doing a similar retrofit you may view my hal

files. Some of the things I added to the hal files allow the use of external start

and stop buttons. The machine has an x-y joystick plus a z joystick each with a center

"rapid" button. Also I have an encoder input. The gains for the joystick and encoder

can be adjusted up or down using unused keyboard keys or buttons added to the

Axis interface panel.

bridgeportS2I2_postgui.hal file

panel.xml file

I_O_status.xml file

AXIS Screen: